The Best Around Underground

AK Industries, Inc. is a leading producer of fiberglass and polyethylene products for the wastewater industry that provides solutions for both centralized and decentralized wastewater management.

Welcome to AK Industries

With a history spanning over four decades, AK Industries specializes in manufacturing high-capacity fiberglass lift stations for municipalities to ejector basins for individual residences.

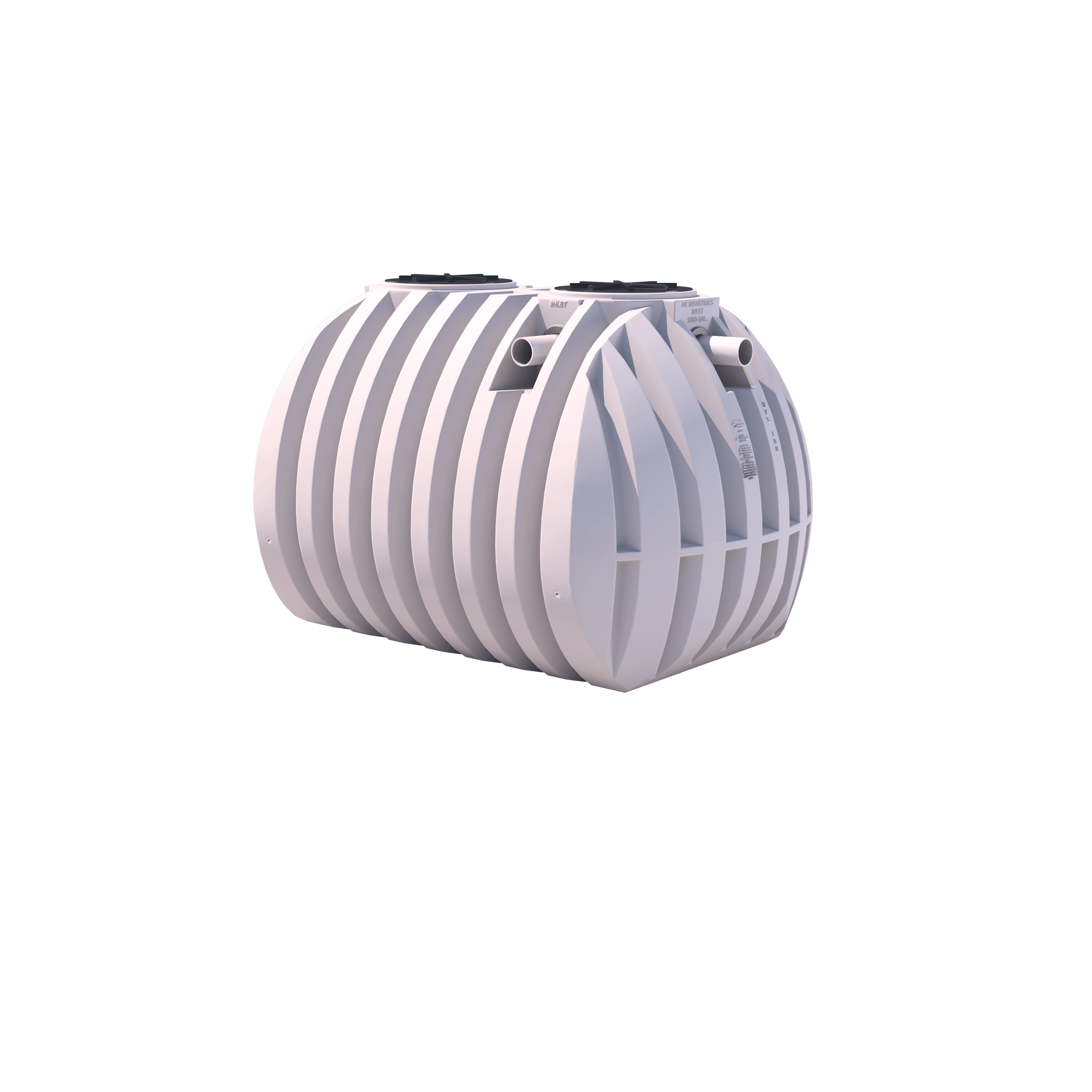

AK also manufactures a comprehensive line of polyethylene septic tanks, sump pits, basins, and plumbing accessories. Beyond our standard offerings, we provide custom molding services, encompassing product development and production to meet the specific needs of our customers.

Our Products

Why choose Ak industries

Innovative solutions, Superior quality

Expertise & Innovation

Leveraging over four decades of experience, AK Industries combines industry-leading expertise with a commitment to innovation, delivering state-of-the-art water and waste management solutions.

Quality Assurance

Our rigorous quality control process ensures that every product — from fiberglass lift stations to polyethylene septic tanks — meets the highest standards of durability and performance.

Custom Solutions

With our custom rotational molding services, we go beyond off-the-shelf products to create solutions that perfectly align with your project’s unique requirements.

Sustainability & Efficiency

We’re dedicated to environmental stewardship, manufacturing products that provide robust solutions for environmental pollution that endangers human health and degrades the environment. AK Industries searches for ways to reduce the impact of our manufacturing processes through optimizing resource consumptions such as lowering scrap rates, reducing the energy costs of our buildings and processes, and offering products that have a lower environmental impact than comparable concrete technologies.

Resources

Contact us today

Transform Your Wastewater Management with AK Industries.

At AK Industries, we’re not just engineering solutions; we’re building the foundation for tomorrow’s water and waste management infrastructure. Let us prove to you why we are still “The Best Around Underground!”

Fiberglass sales

2055 Pidco Dr.

P.O. Box 640

Plymouth, IN 46563

Phone: 574-936-6022

Fax: 574-936-5811

Poly, Wastewater & Custom Sales

1919 Jim Neu Dr.

P.O. Box 640

Plymouth, IN 46563

Phone: 574-936-2542

Fax: 574-936-2298